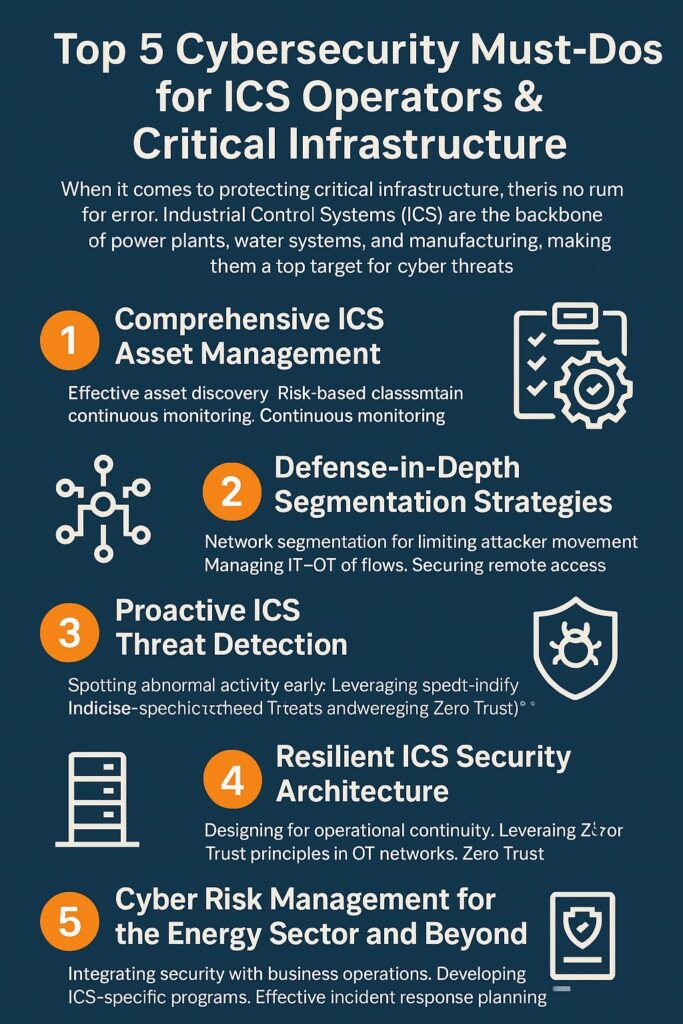

When it comes to protecting critical infrastructure, there is no room for error. Industrial Control Systems (ICS) are the backbone of power plants, water systems, and manufacturing, making them a top target for cyber threats. If you’re an ICS operator, staying ahead of these risks isn’t just essential.

But with so much information out there, it can be tough to know where to begin. That is why we have narrowed it down to the top five cybersecurity must-dos you can act on today. Simple, clear, and effective steps to help you strengthen your defenses and keep your systems running safely and smoothly.

Cybersecurity Implications That Need To Be Considered When Integrating Smart Factory Systems?

Integrating smart factory systems brings advanced capabilities, but it also introduces serious industrial cybersecurity risks. As connectivity grows, so does the threat of data breaches, ransomware, and system disruptions. Legacy systems, remote access points, and AI-driven automation can all expand the attack surface if not properly secured. Even simple human errors can open the door to major cyber threats.

These risks are heightened by the convergence of IT and OT systems, which can expose sensitive industrial processes to traditional cyber threats. Supply chain vulnerabilities and unsecured third-party connections add further complexity. Without proper segmentation and access controls, attackers can move laterally across networks undetected.

To stay protected, organizations need a strong cyber risk management strategy that identifies vulnerabilities, mitigates threats, and ensures business continuity. Investing in reliable industrial cybersecurity solutions, including real-time monitoring, regular updates, and a zero-trust approach, is key to securing operations. Cybersecurity must be built into every layer of the smart factory from the cloud to the shop floor to maintain safety, efficiency, and resilience.

1. Comprehensive ICS Asset Management

Before you can protect your industrial environment, you need complete visibility into what exists in your network. Comprehensive ICS asset management creates the foundation for all other security efforts by enabling accurate risk evaluation and proactive defense planning.

Effective asset discovery and visibility across OT networks are essential for securing industrial environments. Passive monitoring helps identify devices without disrupting operations, especially fragile legacy systems. Specialized tools are needed to detect proprietary protocols and undocumented “shadow” assets that pose hidden risks.

Risk-based classification helps prioritize critical assets and understand system dependencies. Mapping communication flows reveals attack paths and supports anomaly detection, helping teams detect threats early.

Advanced ICS asset management tools use network traffic analysis for non-intrusive monitoring and can integrate IT and OT systems for unified visibility. Continuous monitoring ensures asset data stays current as environments evolve, forming a strong foundation for secure communication control.

Automated inventory updates, real-time alerts, and historical tracking further enhance visibility, enabling faster response and stronger cyber resilience across industrial infrastructures. These capabilities support proactive risk management, regulatory compliance, and streamlined incident response in dynamic OT environments.

2.Defense-in-Depth Segmentation Strategies

Network segmentation is vital for limiting attacker movement within industrial environments. Using frameworks like the Purdue Model, organizations can create secure zones with clear trust boundaries, access controls, and real-time monitoring to detect unauthorized activity and reduce lateral threat movement.

Careful management of IT-OT data flows ensures operational needs are met without exposing systems to unnecessary risk. Secure remote access requires strong protections, including multi-factor authentication, jump servers for session control, and strict vendor access policies.

For legacy systems, micro-segmentation and compensating controls help protect unpatchable devices. Unidirectional gateways further reduce risk by allowing outbound data flow only, ensuring secure communication without exposing critical assets to external threats. These layered defenses form the backbone of a resilient ICS security strategy.

3. Proactive ICS Threat Detection

Even with strong defenses, advanced threats can still breach industrial environments. Proactive threat detection in ICS focuses on spotting abnormal activity early to prevent disruption and ensure resilience against sophisticated attacks targeting critical infrastructure.

Deep packet inspection of industrial protocols and anomaly detection help identify suspicious commands and behavior, even when attackers use legitimate tools. Establishing baselines for normal operations improves the detection of unusual patterns and supports faster incident response across OT networks.

Integrating IT and OT security operations enhances visibility, coordination, and response accuracy. ICS-specific playbooks ensure security actions don’t harm critical processes, while collaboration balances data protection with operational safety and continuous system availability.

Advanced threat hunting, tailored to ICS environments, leverages real-time monitoring, behavioral analytics, and industry-specific threat intelligence. This approach helps identify living-off-the-land techniques, configuration tampering, and unauthorized access attempts across complex industrial networks. Continuous tuning of detection models and human-in-the-loop validation further refine the alert quality and reduce response time.

4. Resilient ICS Security Architecture

Resilient ICS architectures are designed to maintain critical operations even during cyberattacks. In industrial environments, downtime can cause severe consequences, so resilience focuses on operational continuity under adverse conditions, ensuring safety, reliability, and availability.

Fail-safe designs prioritize safety, while redundancy planning and safety instrumented systems ensure functionality despite disruptions. These systems can isolate failures and maintain essential services while remediation occurs.

Supply chain risk management, including vendor assessments and hardware verification, helps prevent compromised components from entering the environment and reduces third-party risk exposure.

Zero Trust principles in OT networks enforce least privilege access, secure machine-to-machine authentication, and continuous system validation. Layered protections, such as micro-segmentation and real-time anomaly detection, strengthen the defense, reduce attack surfaces, and support ongoing operations even when threats bypass traditional controls.

5. Cyber Risk Management for the Energy Sector and Beyond

Comprehensive cyber risk management integrates security with business operations, ensuring alignment between cybersecurity efforts, operational needs, and business goals. Developing an ICS-specific program involves adopting frameworks like NIST CSF and IEC 62443, building strong governance, and forming cross-functional teams. This structure supports clear responsibilities and balanced decision-making across departments and disciplines.

Incident response planning includes tabletop exercises, recovery prioritization, and collaboration with external partners to improve readiness and coordination. Effective response plans also address supply chain vulnerabilities and ensure continuity under pressure.

Measuring OT security posture through KPIs, risk reduction metrics, and compliance tracking provides insight into program effectiveness, helping organizations improve resilience and demonstrate the value of their cybersecurity investments. A mature risk management strategy also fosters regulatory confidence and long-term operational stability.

Implementation Roadmap for Defender Operators

Implementing industrial cybersecurity requires a clear roadmap that balances quick wins with long-term strategies. Early actions like network monitoring, access control reviews, and segmentation offer fast risk reduction.

Sustained progress depends on proper resource allocation and executive support. Framing security in terms of risk reduction and operational continuity helps gain buy-in beyond compliance.

Cross-functional team development is key. Bridging the IT/OT gap through role-specific training ensures collaboration. Security professionals need operational insight, while engineers and operators need cybersecurity awareness.

A phased implementation plan should include detailed assessments, goal setting, and realistic timelines. Regular reviews and adaptive planning help maintain momentum as threats evolve. Metrics-driven evaluations ensure accountability and continuous improvement.

Leveraging lessons learned from past incidents and aligning with industry frameworks ensures a resilient and scalable cybersecurity program. This strategic approach enables defender operators to strengthen security while aligning with business and operational needs.

FAQs

- What separates industrial cybersecurity from traditional IT security?

Industrial environments prioritize availability and safety above all else, with systems that often can’t be patched or updated like IT systems. ICS security must work within strict operational constraints, using specialized tools designed for industrial protocols and equipment that may be decades old.

- How can organizations with limited budgets prioritize ICS security investments?

Start with comprehensive asset inventory and network visibility, then implement basic segmentation. These foundational elements provide significant protection without major investments. Focus first on securing remote access points and monitoring for abnormal activity, then build more advanced capabilities over time.

- What warning signs might indicate an ICS security breach?

Look for unexpected engineering software usage, unusual network connections between systems that rarely communicate, configuration changes outside maintenance windows, and operational anomalies that can’t be explained by mechanical issues. Remember that attackers often use legitimate tools to avoid detection.