Planning a 3D printing project is exciting, but costs and timelines can quickly change if you don’t know what drives them. From design choices to material selection and production volume, small decisions can have a big impact on your final budget and delivery date. Whether you’re creating a prototype, a custom part, or a short production run, understanding these key factors helps you avoid surprises and make smarter choices. This guide breaks down what really affects pricing and turnaround time, so you can plan with confidence, stay on schedule, and get the most value from your 3D printing investment.

The Real Cost Picture Goes Way Beyond That Per-Part Number

Here’s the thing—that price per part line on your quote? Just the tip of the iceberg. Hidden costs routinely double what buyers expect to pay.

Every Cost Layer You Actually Need to Plan For

Each project carries pre-print expenses—fixing STL files, running design-for-manufacturing reviews. Next up: actual machine runtime and raw material. Then you’re into support cleanup, surface finishing, inspection protocols, packing, freight. And here’s what catches people off guard: iteration risk. When a print bombs or won’t fit your assembly, you’re paying to re-run it. Throw in admin overhead or rush fees you never saw coming. Research on additive workflows shows medical teams can knock out planning models in two hours flat using 3D software and printers —proof that speed matters, but only when your whole workflow is dialed in.

The Cost-Speed Tradeoff Nobody Mentions Upfront

Before you jump at the cheapest bid, get this: rock-bottom pricing usually means the longest wait, while expedited service can triple your spend—and neither one guarantees you’ll be happy with the result. Budget shops batch jobs to max out chamber space economically, so your parts sit in queue. Express providers promise you’ll jump the line, but then hit bottlenecks in curing ovens or finishing capacity that simply can’t speed up.

Knowing these 3D printing pricing factors means you make smart calls instead of taking shots in the dark, especially when weighing turnaround expectations from a 3D printing service Seattle teams rely on for steady production.Looking past the sticker price helps you spot where delays really happen and how they affect your delivery schedule. In the long run, that clarity leads to fewer surprises and more dependable results.

Which Technology You Choose: Your Biggest Cost and Timeline Lever

Those tradeoffs aren’t random. They’re driven by your technology selection—the single biggest decision that shapes both your final bill and when parts show up.

SLA: Beautiful Surfaces, Labor-Intensive Cleanup

SLA delivers gorgeous surface finish. The catch? Support removal takes serious labor that first-timers routinely underestimate. Support density, how you orient parts, resin chemistry, post-cure protocols—all control what you pay. Studies prove that printing at 20° orientation burns 26% more resin material, meaning 26% higher cost. Your setup decisions have real budget consequences. Timeline hinges on curing capacity and how many parts share each build.

SLS and MJF: Powder Tech With Volume Advantages

Powder methods like SLS and MJF? They ditch the support headache completely. But cost now depends on how well your parts pack into the build volume. More parts per run cut unit price, yet filling that chamber can push your start date out.

Cooling periods and de-powdering equipment create schedule friction. Dyeing or tumbling add time and expense, but cosmetic parts often demand them.

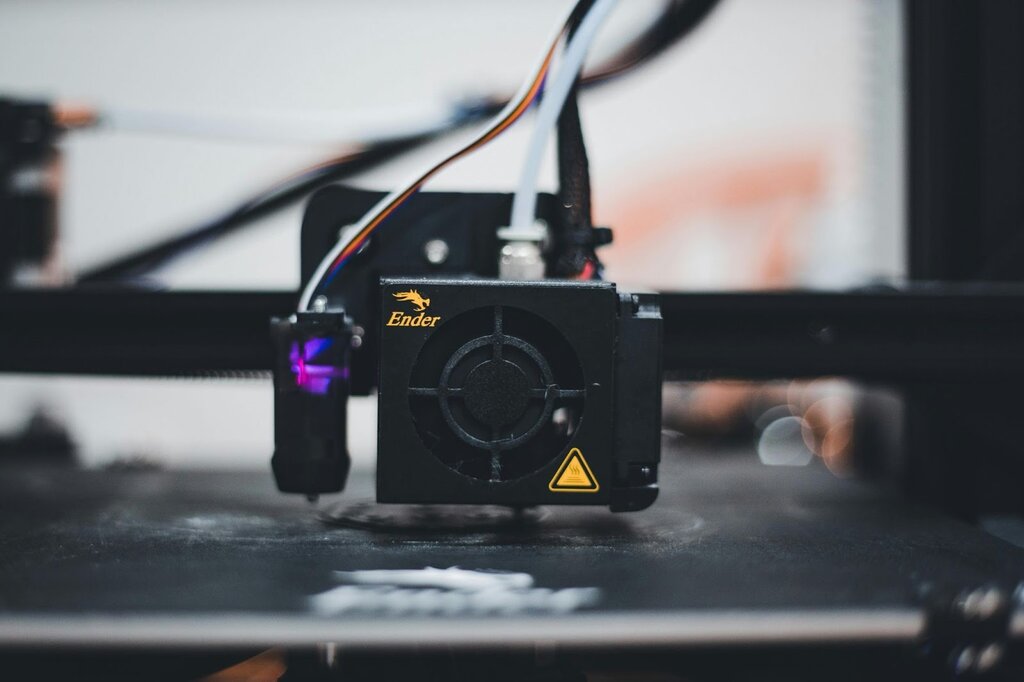

FDM: Fast and Cheap Until Looks Matter

FDM gives you the easiest entry point and quickest machine time for straightforward shapes—until you need smooth surfaces or precision, then those layer lines and supports destroy your cost advantage fast. Print speed, infill density, nozzle diameter, layer thickness—you’re constantly trading quality against clock. Need tight tolerances or great cosmetics? FDM gets pricey because finishing labor takes over the quote.

Metal AM: Real Performance, Complex Price Stack

When polymer won’t do the job, metal additive gives you functional parts—but brace yourself for a cost structure that includes heat treatment, EDM support removal, and mandatory stress-relief cycles adding weeks to your schedule. Build prep, powder management, HIP or stress relief, CNC post-machining, inspection protocols—it all stacks up. Scarce machine availability makes 3D printing turnaround time unpredictable unless you reserve capacity early.

Material Choice: The Sneaky Driver of Cost and Availability

Process sets your foundation, but material selection writes the final budget—because that innocent dropdown menu actually controls mechanical properties, failure probability, and whether your vendor can start tomorrow or a month from now.

Engineering Polymers Shift Economics Fast

With polymers, the jump from commodity to engineering grades isn’t just strength—it’s tighter processing windows and supply-chain headaches that hit both price and lead time. PA12, PA11, polycarbonate, ULTEM demand elevated temperatures and environmental controls. Flexible stuff like TPU slows builds and racks up reject rates.

Specialty Resins Bring Certification Baggage

Resin systems add more variables. Formulations for impact toughness, heat deflection, or biocompatibility pile on certification requirements, handling rules, and documentation work. Standard resins stay affordable; dental-certified or flame-retardant options can double your quote from traceability and compliance alone.

Material in Stock Protects Your Schedule

Beyond spec sheets lies a practical truth: supply-chain chaos can delay you more than any complex geometry, making material availability a timeline risk you need to actively manage. Stick with common stock materials for faster 3D printing lead time, pre-approve substitutes to dodge schedule slips, lock material commitments early for long programs. In areas with heavy aerospace and tech activity, working with a 3d printing service Seattle customers trust can also compress shipping lag and accelerate iteration when you’re refining intricate assemblies.

Order Volume and Timing: Batch Strategy Controls Unit Economics

Finish requirements affect individual components, but quantity and scheduling choices govern batch economics—where setup costs, build nesting, and post-processing capacity create non-linear pricing curves. Research confirms only five models fit a DLP platform horizontally versus 15 vertically, yet horizontal printing took merely 43 minutes compared to 100 minutes vertical, proving batching strategy matters as much as single-part speed.

Smart Consolidation and Nesting

Within any quantity range, intelligent batching and consolidation let you exploit nesting efficiency and shared setups to drop unit cost without sacrificing schedule flexibility. Merge parts with identical material and resolution specs, standardize finish and color across batches, approve default orientations to prevent holdup.

Your Burning Questions About Cost and Timeline

What matters more for price: part volume or overall size?

Depends on your process. FDM and SLA charge mostly by build height, whereas SLS and MJF focus on volume and powder usage. Always verify process-specific constraints before finalizing designs.

Can I get solid cost estimates without CAD files?

Not really. Pricing hinges on geometry complexity, support structures, exact dimensions. Ballpark estimates exist, sure, but they’re routinely off by 50% or more without actual CAD analysis.

Why do tighter tolerances extend turnaround even when print time stays the same?

Because tight tolerances demand more careful build setup, slower print parameters, controlled post-processing, and formal inspection steps—all adding days beyond actual machine operation.

Wrapping Up: Taking Control of Your 3D Printing Budget and Timeline

Managing your 3D printing project cost and 3D printing lead time starts with seeing the complete cost picture, not just that per-part sticker price. Technology selection, material availability, geometry decisions, tolerance specifications, smart batching—they all influence your final invoice and delivery date. Standardize where it makes sense, pre-approve alternatives, plan finishing steps upfront, and you’ll protect both budget and schedule. Teams that master these levers consistently get better pricing, quicker turnaround, fewer headaches—transforming 3D printing from a risky bet into a dependable manufacturing tool.